Headquartered in Brasilia and operating throughout the country, CPC accumulates more than 1 million square meters in executed works, some of up to 4,000 tons.

After forty years of experience, the factory occupies 25,000m² of area where all stages of the structure manufacturing process are developed, from design and calculations, to manufacturing and assembly studies.

We have a team of professionals prepared to propose appropriate and versatile solutions to customers in the application of steel in civil construction.

Always investing in technological development, with a high capacity for evolution and constant updating, CPC Estruturas has achieved a prominent position in the Midwest market, in addition to being the most active in the Brasília market.

From the design to the completion of the work, all details regarding deadlines and technical specifications are carefully considered. The ultimate goal is to ensure total customer satisfaction, offering security and peace of mind.

In more than four decades of activity, the concern with quality and attention to the smallest details have been conquering more than customers. Working for large companies in the country, CPC’s greatest merit is the credibility deposited in it by these customers, who are proud to call them partners. And this partnership is demonstrated after the completion of the first work: whenever they need metallic structures in other developments, they return to CPC.

For 49 years we have been designing metallic structures for airports, bridges, viaducts, multi-story buildings, convention centers, shopping malls, industrial complexes and many other types of works. Always with a high standard of quality and safety.

The manufacturing process follows a strict quality standard certified by ISO 9001:2015 and CRCC Petrobras.

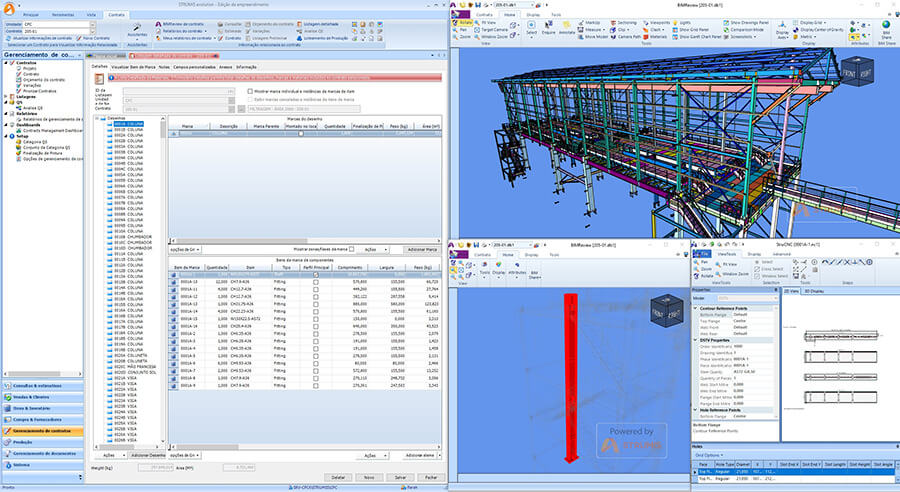

Each project is produced using state-of-the-art CNC equipment integrated with a detailing and management system that adapts to the needs of the work.

All this is in line with excellent dimensional and quality control in the production of each structural element such as cutting, drilling and typing of welded and laminated profiles, plating and angles.

Technology is present at all stages of creation of client projects. We faithfully follow the calculations and dimensioning of the structural elements carried out digitally and in an integrated way, guaranteeing agility and security.

The structure manufacturing process is carried out entirely at CPC Structures, in accordance with rigorous standards and quality norms established at each stage so that the final product has an excellent finish.

The constant investment in technology and updating of our technical team ensures precision and agility, reducing costs and optimizing communication between the factory and the customer.

To monitor and control the manufacture of metallic structures, we use an integrated production management system that uses information from the previously detailed BIM model to obtain all the geometric information of the parts and assemblies to be manufactured. This automatic process of obtaining data optimizes factory operations and minimizes the possibility of errors, making the entire production process more reliable, enabling online consultation of the production status of each element to be produced. Investment in state-of-the-art technology is a constant in the improvement of CPC Structures.

Technology, technical knowledge and commitment to results in carrying out the best projects with metallic structures throughout Brazil.